A devastated Joganji River runs an area of steep terrains and fragile ground which cause frequent sediment collapse and rockfall. The area also receives a lot of snow, limiting available construction period. Under such severe conditions, we have developed and adopted a variety of innovative construction methods.

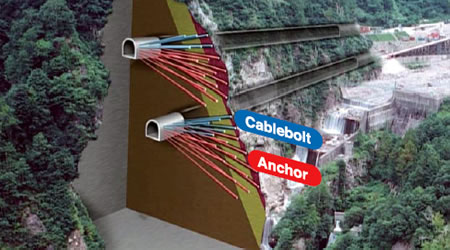

1. Countermeasure for Rock Mass Collapse on the Right Bank of Shiraiwa Sabo Dam

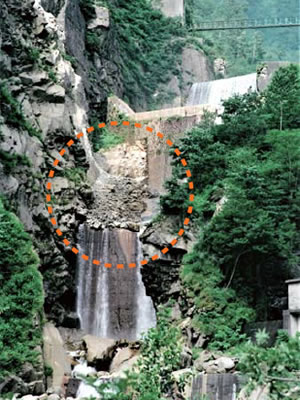

Rock mass on the right bank of Shiraiwa Sabo Dam has a number of cracks, which have repeatedly caused collapse. In June 1994, a large-scale collapse occurred (with a volume of about 1,700 m3). If a large volume of collapsed sediments piled up in the drainage (notch) of Shiraiwa Sabo Dam, water and debris will flow on the embankment of the left bank, which is a weak point of Shiraiwa Sabo Dam, and may ultimately destroy the dam. To tackle this issue, the construction of rock reinforcement on the tirht bank was started in 1999. The new methods, such as digging a tunnel inside the rock, and driving a linear anchor bolt from inside the tunnel toward its surface, were adopted in order to fix it in the construction work.

We dug a tunnel and hammered about 890 anchor bolts and cable bolts to stabilize the rock mass.

We dug a tunnel and hammered about 890 anchor bolts and cable bolts to stabilize the rock mass. The collapse of the right bank of Shiraiwa Sabo Dam (1994)

The collapse of the right bank of Shiraiwa Sabo Dam (1994)

2. Unmanned Technique

Since 1973, the unmanned tecnique has been introduced on the sites hazardous to slope collapse, rockfall, etc. in the Tateyama Caldera.

Unmanned excavation machine has a wireless equipment that allows us to remotely operate the machine from a safe operation room. Thanks to this feature, the excavation works on the dangerous sites have been much safer. CCTV camera installed on the unmanned excavation machine makes it possible for our worker to operate the machine in real-time while watching the monitor in the operation room.

View of the construction with the unmanned technique

Unmanned backhoe (a photo taken in 1983)

View of the inside of unmanned machine operation room

3. Movable "Shutter" Gate Sabo Dam

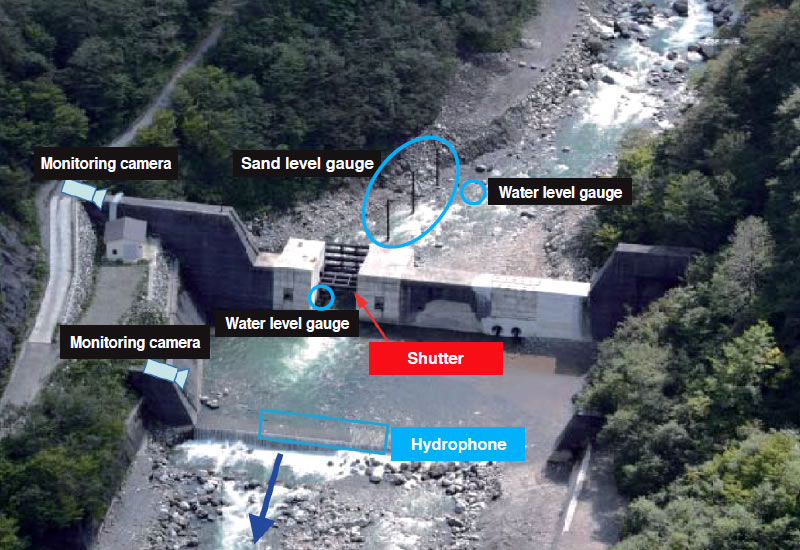

Tateyama Mountain Area Sabo Office has developed Sabo Dam (Myoju Sabo Dam) with movable shutter.

Its shutter opens at a normal time. In the event of large-scale sediment collapse occurs in the upstream or when sediment flows at a stroke due to floods, the shutter is closed to prevent sediment discharge.

The observation equipment in and around the Sabo dam have been installed. Based on the observed data, the effective operation when to open or close has been considered.

4. SABO Soil Cement Method

ISM construction method applied for Sugodani groundsill works

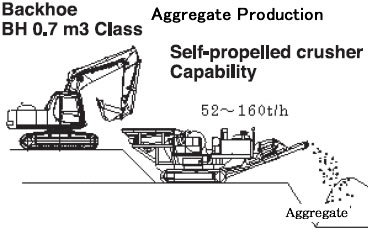

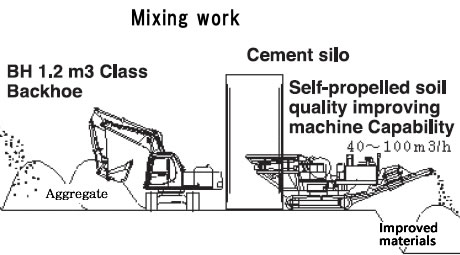

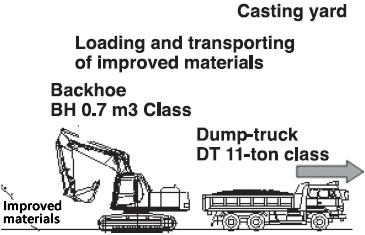

SABO Soil Cement Method, ISM (In Situ Mixing) and INSEM (IN-situ Stabilized Excavation Materials) are to mix sediment generated from the construction site with cement, for production of the materials of Sabo facilities.

These methods are expected to reduce the environmental burden, reduce construction cost, and shoten construction term.

INSEM construction method applied for Yukawa No.12 Sabo Dam